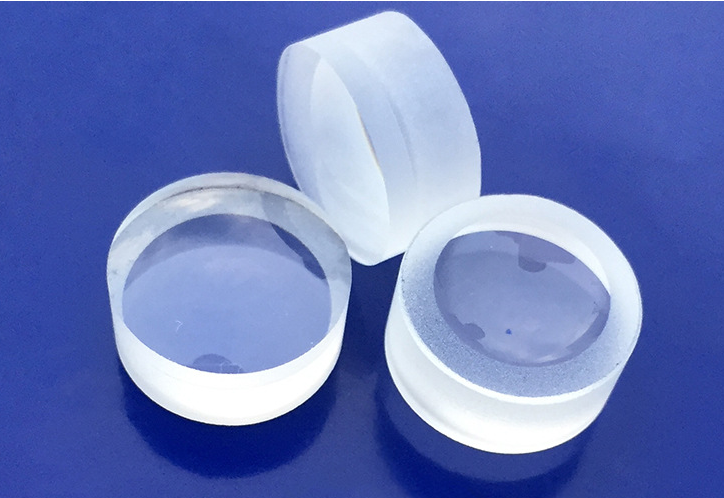

An optical lens is usually a lens group composed of several lenses. How do the lenses connected together? This issue will introduce the gluing process of optical lens and learn its function in the lens manufacturing process.

Definition of gluing process:

●The gluing process of optical lens mean the process that two or more lenses or plane mirrors are bonded into one optical components according to certain technical requirements by gluing method and optical-cement method.

Gluing requirements:

In actual production, the gluing of optical lenses has two requirements:

The first is to ensure the center deviation and angle deviation. For the lens, ensure the center deviation of the lens; The second is to ensure that the glued surface realizes "zero defect" gluing, that is, to ensure that the glued polished surface does not reduce the requirements for surface defects due to gluing and, does not affect the surface shape of the non glued surface due to gluing.

There are two gluing methods for optical lenses, namely, gluing method and optical-cement method. The gluing method is to synthesize several optical lens glues into complex optical components using optical grade transparent glue. The optical-cement method is to combine several lenses into a complex optical lens group by the attraction of molecules between the polished surfaces of parts.

What is the function of gluing optical lens?

1. Improve image quality

In order to ensure that the photoelectric instrument has good imaging quality and imaging requirements, for example, the gluing of positive and negative lenses can eliminate spherical aberration and chromatic aberration.

2. Reduce light energy loss and increase imaging brightness

In general optical materials, the reflection loss at the interface between air and glass is 5% - 6%, while the reflection loss at the interface between optical glue and glass is only 0.1% or less. Therefore, gluing the optical lenses together can reduce the number of interfaces between air and glass, thus reducing the loss of light energy and increasing the imaging brightness.

3. It can simplify the processing of optical lens

Since the gluing can compensate for the small difference in the radius of curvature of the gluing surface, the accuracy requirements of the gluing surface can be appropriately reduced.

4. Protect the surface of optical parts

In order not to damage the optical dividing surface, polarizing plate or the surface of the body part, the protective glass is often glued on the surface of the part to protect these surfaces. For example, the lens protection glass at the outermost layer of the mobile phone lens is mainly used to prevent the lens from being damaged by foreign matters.

Post time: Aug-29-2022